What type of wood should I burn in my stove or fireplace?

Your wood burning appliance will perform best and last longer if you burn cordwood that has been cut, split and dried for a minimum of ½ to 1 year. You should never burn pressure treated wood, driftwood, painted wood, particleboard or wood with nails in it. These woods contain chemicals that can damage your stove as well as harm the environment.

There are several factors that impact your equipment’s performance. These include the type of wood you burn and whether or not the wood has been properly dried. Generally we recommend using a hardwood such as oak or maple. But remember, the most important thing is to use wood that is cut and split to the right size and has been properly dried.

What are some of the other qualities of wood that I should be concerned about?

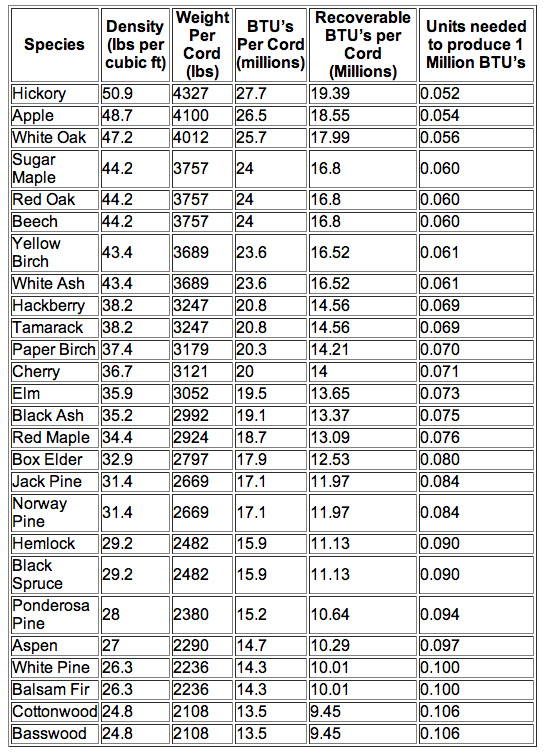

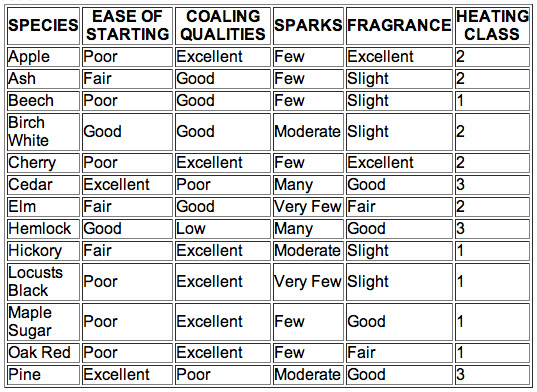

Different types of wood have different heating values. Each species of wood has its own characteristics, yet all wood has roughly the same energy content. The different species vary only in density. If you’re buying wood, expect to pay more for a cord of mixed wood containing a lot of oak and hickory, for example, than an equivalent measure of mostly pine. Generally speaking, you’ll get much more heat from hardwood than from softer, lighter wood. Most firewood you purchase will be green and have a fair amount of water in it. It takes a minimum of six months of air drying for wood to be considered seasoned and ready for burning. When selecting wood, also take into consideration ease of splitting, ease of ignition and burning, how much smoke it produces and its “coaling” qualities. In the chart above, “coaling” refers to the ability of a species of wood to form a long- lasting bed of hot coals when burned. Coaling qualities improve with higher density. And in the heating class column, the lower the number the better.

How clean do wood stoves burn?

Wood smoke is often full of unburned wood particles and other by-products of the combustion process. Test labs can measure the amount of particulate in the smoke. Before the government started regulating woodstoves in 1988, the average stove produced about 70 – 80 grams per hour of particulate matter. By 1992, EPA Phase II required that all non-catalytic stoves produce less than 7.4 grams of particulate per hour and catalytic stoves produce less than 4 grams per hour. Catalytic requirements are more stringent because the effectiveness of the catalyst degrades over its life expectancy, while non-cat stoves remain consistent.

What does a catalytic combustor do?

All woodstoves today have been required to pass very strict clean air standards. Manufacturers accomplish this through two types of technology. One is by closing a damper and routing the smoke through a catalytic combustor. This is a honeycomb looking component designed in the appliance that reaches extremely high temperatures. As the smoke passes through the combustor, the by-products of the combustion process is burned. A combustor needs to be cleaned regularly (at least annually) and periodically replaced (after about 10,000 hours of operation).

The other technology uses a series of secondary air tubes in the top of the firebox. These tubes draw a precise amount of heated air, inject it into the fire and actually cause any particles in the smoke to burn. There is no regular maintenance required on secondary air tubes. However, they should to be replaced every four or five years for best performance.

What stove is better, a catalytic or non-catalytic?

There is much debate over this question. Both technologies will produce clean and efficient burns. Consider that a non-cat stove is usually easier to operate. There is one air control. If you want more heat, give the fire more air - for less heat, reduce the amount of air. Catalytic stoves use a damper to engage the combustor that must be opened whenever the door is open or for re-fueling. The combustor and flue gas temperature must be monitored to know when it is appropriate to close the damper. A combustor needs to be cleaned regularly (at least annually) and periodically replaced (after about 10,000 hours of operation).

How do I keep the glass clean on my wood appliance?

The deposit you see on the glass of your wood burning stove or fireplace is creosote, one of the by-products of burning wood. There are three things you can do to help reduce the amount of creosote that accumulates on the glass. First of all, be sure your wood is well seasoned. The more moisture in the firewood, the more creosote will be deposited on the glass. Also, be sure to burn your appliance with the air control open as much as possible. By doing this, a large volume of air is directed over the glass. This “air wash” over the glass helps push smoke away from the glass and reduces deposits on the glass. Reducing the amount of air to the fire reduces the “air wash” effect and will allow more deposits on the glass. The final thing you can do to help reduce the amount of creosote on the glass is to build smaller, but hotter, fires. Hotter fires will burn more of the ingredients of the smoke and will result in more heat for your home, less smoke in the environment and will reduce the amount of condensation of creosote. Burning a hot fire will normally help burn off heavy deposits on the glass.

If deposits remain, how can I clean the glass?

First of all, be sure the fireplace and the glass are completely cold. Never attempt to clean a hot appliance. Wipe off the inside of the glass with paper towels or a crumpled newspaper to remove any dry powdery material. If the creosote on the glass is gummy and sticky, burn a hot fire for several hours with seasoned wood to try and burn off the deposit before using a cleaner. We sell a specialty glass cleaner that will help remove stubborn deposits. Incidentally, be careful not to allow the cleaner to drip onto plated metal parts such as gold and brass - discoloration of these parts can occur. Some old-timers still use an old-fashioned method to clean glass by dipping a dampened wad of newspaper into fine wood ashes and scrubbing the glass with it, the finishing up with a clean, damp newspaper.

Can my wood stove be converted to gas?

No! Don’t do it. It is extremely dangerous, it is also illegal.

How about my wood-burning fireplace? Can I convert it to gas?

This is a different story. There are several products available to convert a wood fireplace to gas, such as gas logs, a gas fireplace insert and even a gas stove. We normally need to evaluate the fireplace to determine what options will be best suited for your application. We also suggest you come to the showroom so you can see first hand how this equipment looks and performs.

How long will my wood burning appliance hold a fire and how much space will it heat?

There are several variables that affect this question - the type of wood, how seasoned it is, the rate at which your home loses heat and where the air control for the appliance is positioned. The biggest variable though, is the size of the firebox - how much wood can you get inside? This is measured in cubic feet. A small stove will have a 1.4 cubic foot firebox and may be able to heat up to 500 – 600 square feet, while a large, full size stove will have a firebox size of 3.0 cubic feet and heat up to 2000 square feet of space. A large fireplace will be over 4 cubic feet and capable of heating 2000 – 3000 square feet of well insulated space.

Why won’t my chimney draft properly?

This can be a very complicated topic as there can be many factors that result in why a wood burning stove will not draft properly. Stoves must be installed to appropriate standards, which means they are safe. But the code does not mean that it will perform properly.

The correct size chimney is crucial to a stove’s performance. The old school way of thinking said the bigger the chimney, the better the draft. As stoves burn more efficiently, there is less heat going up the chimney. As a result, there may not be enough heat in an oversized chimney for the stove to operate correctly. The majority of wood burning stoves require a six inch diameter chimney. Most manufactured zero clearance wood burning fireplaces will require an eight inch chimney.

Smoke should travel straight up. Every elbow or offset creates a point of resistance that can cause problems. Remember that it is always best to keep the chimney as straight as possible and as warm as possible (or, inside the house) for as long as possible.

Chimneys that run up the outside of a home tend to be very cold. It takes considerably more heat to create a draft in an outside chimney than a chimney that is installed on the inside of the home. Prefabricated metal chimneys on the outside of a house should be built into an enclosed insulated chase.

Another significant problem in a home, especially a newer home, is negative air pressure. Negative air pressure can cause a stove to not draft properly. As homes have been built tighter in recent years, there is less air to replace air that is used in the combustion process. Basements can have a considerable negative air pressure problem. Kitchen fans, clothes dryers and bathroom exhaust fans also remove air from your home. A wood stove can only function properly if there is a sufficient amount of fresh air available for it to burn properly.

External factors such as the design of the roof, nearby trees, wind patterns and the location of the home can have an effect. Because there can be so many variations and factors involved, your specific circumstances can be discussed when you purchase your stove.

Occasionally, a stove that is drafting poorly is the result of a careless installation. The ceramic blanket on top of the baffle in the stove can be knocked out of place and block the flue gases and smoke from exiting the stove. It isn’t uncommon for people to stuff rags or insulation in the chimney to prevent cold air from entering the home during construction or during periods of non-use. Then, when a fire gets built, someone forgets to remove the material.

What’s the difference between convective heat and radiant heat?

Radiant heat, heats objects such as people, furniture and the furnishings in a room. Convective heat is air that has been warmed by moving through a heat exchange area. Think of convective heat as air moving through a heated confined space. Radiant warms objects, like the heat from the sunshine.

What are the proper clearances for my wood burning stove?

Detailed drawings and instructions regarding the clearance requirements are available for any wood burning stove that you purchase from a dealer in the appliances owner’s manual. Older stoves, meaning an untested or unlisted stove, must comply with a set of “default requirements” in order to insure a proper installation.

How do I childproof my stove?

The heat energy coming from a gas appliance can be quite intense and most little ones will feel this heat as they approach a stove or fireplace and will stay away from it. However, if you are concerned, we have several screen shields to protect your children from the equipment.

How do I prevent smoke from entering the room when I open the door?

Open the door a crack, wait a few seconds, and then open the door slowly. This will greatly reduce the possibility of the door drawing the smoke into the room.

How often do I need to clean my chimney?

According to NFPA 211 (the National Fire Protection Association standard), chimneys should be inspected and cleaned if necessary, at least once a year.

I’ve heard the term “Negative Air Pressure”. What is it?

Negative air pressure occurs when the air pressure inside a home, generally in the lowest level, is less than the barometric air pressure outside the house.

As hot air naturally rises in a home, positive air pressure is created in upper levels of the home and negative air pressure in the lower levels. This phenomenon is created by modern construction techniques that restrict the amount of air that infiltrates a home.

In a worst-case scenario, negative air pressure can actually over power the draft in a chimney and draw make-up air down the chimney. Combustion appliances, exhaust fans, range hoods, bathroom fans, central vacuum units and clothes dryers can also pull air from inside the home, contributing to negative air pressure when they operate.

In very tight homes, the outside air/air exchange problem needs to be solved for the entire structure. Sometimes this means installing a mechanical outside make-up air system.

How much should I expect to pay for a wood appliance?

It is unwise to pay too much, but it is worse to pay too little. When you pay too much, you lose a little money, that is all. When you pay too little, you sometimes lose everything, because the item you purchased was incapable of doing the thing it was bought to do. The common law of business balance prohibits paying a little and getting a lot. It cannot be done. If you deal with the lowest bidder, it is well to add something for the risk you run. And if you do that, you will have enough to pay for something better. There is hardly anything in the world that someone cannot make a little worse and sell a little cheaper, and people who consider the price alone are this man’s lawful prey.

By John Rusking (1819 - 1900)

If you have other questions, please feel free to give us a call at (608) 929-4887 or fill out our online contact form and an expert team member will promptly reach out to you!

Chimney Specialists Inc. proudly serves the tri-state area of northeast Iowa, northwest Illinois and southwest Wisconsin, including communities such as Boscobel WI, Dodgeville WI / Mineral Point, WI, Fennimore WI, Madison WI, Middleton WI, Platteville WI, Prairie Du Chien WI, Richland Center WI, Spring Green WI, Mt Horeb WI and Dubuque IA.